New Horizons: What A Test Track Opening Means For Innovation And Quality

A test track opening marks a truly exciting moment, signifying a fresh commitment to pushing boundaries and ensuring excellence. It is, in a way, a declaration that the future of product development, especially for things we rely on every day, will be built on a foundation of rigorous evaluation. This isn't just about cutting-edge vehicles or fancy gadgets; it's about the very core of how we bring reliable, well-performing items into the world for people to use. You know, it's pretty big, actually.

Think about it: before you trust a product, whether it's a new appliance or a vehicle you drive, you want to know it works as promised. This desire for certainty, for verified performance, is a deeply human thing. It's the same feeling you get when you use a tool to check your internet speed, expecting a smooth online experience, or when you receive results from a health check-up, hoping for good news. So, a test track, in its essence, embodies this universal need for proof and dependability.

Today, as we consider the significance of a test track opening, we're really looking at a dedicated space where products, particularly those that move us or assist us, can be pushed to their limits in a controlled setting. It’s a place where questions about durability, safety, and overall function get answered, often with painstaking detail. This commitment to thorough checking, you see, is what separates good from great, and it's something that benefits all of us, every single day.

Table of Contents

- The Core Purpose of a Test Track

- The Science of Performance Verification

- Drawing Parallels: Testing in Our Daily Lives

- What Happens at a Test Track Opening?

- Why This Matters to Everyone

- Frequently Asked Questions

The Core Purpose of a Test Track

A test track, at its heart, serves as a specialized laboratory, but for things that move. It is where theories meet reality, where designs are put through their paces in a very real, tangible way. This kind of facility is absolutely vital for making sure that new ideas aren't just good on paper, but that they truly perform in the physical world. It's a place where every curve, every slope, every surface is designed to reveal the strengths and weaknesses of a product, like a vehicle, before it reaches the hands of the public, you know.

Beyond the Showroom

When you see a gleaming new car in a showroom, it looks fantastic, doesn't it? But its true capabilities, its real character, are not revealed there. They are discovered on the test track. This dedicated space allows engineers and designers to go beyond static appearances and explore how a vehicle handles at various speeds, how its brakes perform under pressure, or how it responds to sudden changes in direction. It’s a bit like checking your internet speed with a tool like fast.com; you want to know the actual performance, not just what's advertised, right?

The track simulates all sorts of conditions, from smooth highways to rough, uneven paths, providing a controlled environment for observation. This is where the vehicle's components, from its engine to its suspension, are pushed to their operational limits. It's where the rubber truly meets the road, so to speak, in a setting that replicates the diverse challenges a driver might face. This systematic approach to checking things out is, in fact, quite similar to how medical professionals conduct various tests to get a complete picture of someone's health, like a comprehensive blood test or a detailed scan.

A Place for Rigorous Checks

Every inch of a test track is built for a purpose: to facilitate rigorous checks. There are sections designed to test high-speed stability, areas for evaluating braking systems, and even specialized surfaces that mimic challenging road conditions, like those with low grip. This allows for repeated, consistent testing, which is absolutely key to gathering reliable data. It's a bit like how you might use an internet speed test tool repeatedly to get detailed results for your download and upload speed, ensuring your network performance is consistent, or how a lab might run a PCR test multiple times to confirm a diagnosis.

These checks aren't just about identifying problems; they're about refining solutions. If a vehicle doesn't perform as expected in a particular scenario, the data collected on the track helps engineers understand why. This information then guides improvements, making the product safer, more efficient, and more enjoyable to use. It’s a process of continuous learning and refinement, ensuring that what eventually reaches consumers is something they can truly depend on. So, in some respects, it’s a very important step in making sure everything works right.

The Science of Performance Verification

The work done on a test track is deeply rooted in scientific principles, involving precise measurements, controlled experiments, and careful analysis of data. It’s not just about driving around; it’s about understanding the physics of motion, the mechanics of engineering, and the subtle ways that design choices impact real-world performance. This scientific approach ensures that every finding is based on objective evidence, rather than just subjective impressions, which is, honestly, what you want for anything important.

Speed and Endurance: A Deep Dive

One of the primary aspects evaluated on a test track is speed, naturally, and how a product performs under sustained high-speed conditions. This involves pushing engines, transmissions, and tires to their limits over extended periods. Engineers monitor everything from engine temperature to fuel efficiency, gathering vast amounts of data. This is quite similar to how an internet speed test checks how fast your download speed truly is, measuring how quickly data travels to your device, or how long a system can maintain optimal performance. You want to know if your connection is fast enough for everyday activities like remote work or streaming movies, right?

Endurance testing, too, is a critical part of this. It's about seeing how a product holds up over time, under repeated stress. This could mean thousands of miles driven on various surfaces, or countless cycles of acceleration and braking. The goal is to identify any potential weaknesses or points of failure before they become an issue for the end user. This rigorous, long-term evaluation is akin to how medical tests, like those for congenital CMV or hepatitis A, provide a snapshot of health over time, helping to confirm or rule out conditions based on how the body reacts and changes. It's about durability, you see.

Handling and Safety: The Critical Measures

Beyond raw speed and endurance, a test track is crucial for assessing handling and safety. This involves evaluating how a vehicle responds to steering inputs, how it corners, and how stable it feels in different maneuvers. Specialized sections of the track, like skid pads or slalom courses, are used to test a vehicle's agility and its ability to maintain control in challenging situations. This kind of precise measurement helps ensure the product is not only fast but also predictable and secure to operate. It’s a bit like a pass/fail test that determines if a system can detect a test agent, ensuring it reacts as it should under specific conditions, so it's a very important step.

Safety checks are, perhaps, the most important aspect of test track operations. This includes everything from evaluating braking distances to testing the effectiveness of stability control systems. Crash tests, while often done separately, are complemented by the data gathered on the track regarding a vehicle's dynamic behavior. The aim is to build products that protect their users, even in unforeseen circumstances. This dedication to safety is comparable to the meticulous process of serologic diagnosis for Lyme disease or pertussis, where every detail matters to ensure accurate results for public health, and that's really what it comes down to.

Drawing Parallels: Testing in Our Daily Lives

While a test track might seem like a specialized, distant concept, the principles behind its operation are, in fact, woven into the fabric of our daily lives. We constantly rely on things being tested, verified, and proven reliable, even if we don't always think about it. This shared need for assurance connects the world of high-performance product development with our everyday experiences, in a way. It’s quite fascinating, really, how similar the underlying ideas are.

Your Digital Connection's Health

Consider your internet connection. How often do you use a tool to check your internet speed? Probably quite often, actually. You want to know how fast your download speed is, how quickly pages load, and if your connection is robust enough for video calls or streaming movies. Tools like fast.com or Xfinity’s internet speed test are designed to give you instant feedback on your network performance, powered by global edge networks. This is a direct parallel to a test track: it's about verifying performance in a real-world scenario, ensuring your digital "vehicle" is running smoothly. It's about knowing your broadband internet and Wi-Fi speed, and getting detailed results for your upload and download speeds, so you can see how fast your home or mobile internet connection really is across every device. This is, you know, very important for modern life.

Just like a vehicle on a test track, your internet connection needs to be put through its paces to ensure it can handle various demands. If your speed test shows slow results, you might look for ways to improve your internet performance, much like engineers refine a product based on track data. The goal is the same: optimal function and reliability for your everyday activities. Testmy.net, for instance, is a powerful broadband speed test that calculates your transfer rate and outputs accurate, reliable, and easy-to-understand results. This kind of immediate, precise feedback is, in fact, what makes these tools so valuable, and it's quite similar to the feedback gained from a physical test track.

Personal Well-being Checks

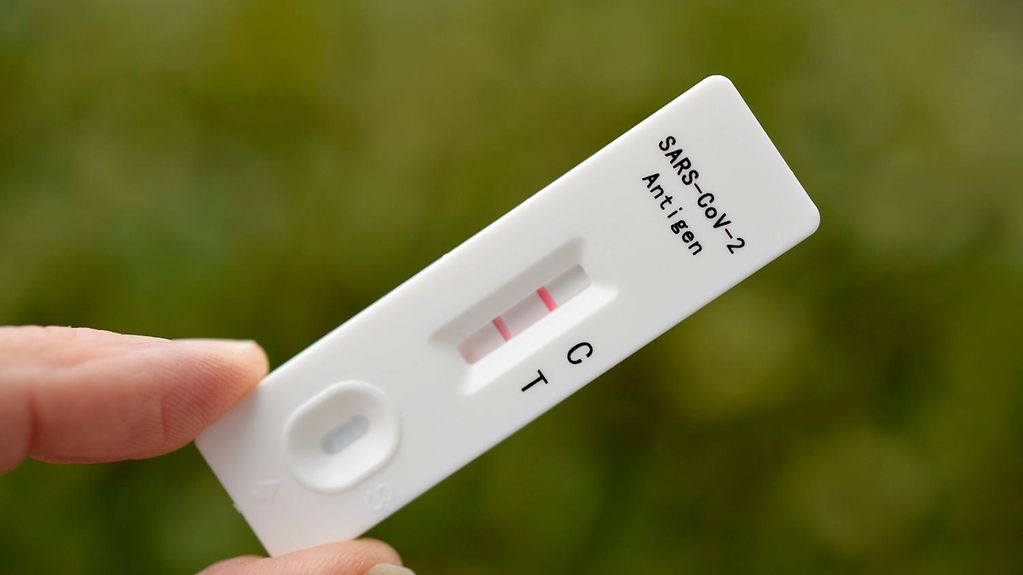

The concept of testing for reliability also extends to our personal well-being. Think about the various health checks we undergo. A blood test can confirm a suspected case of hepatitis A, for example. A health care worker measures swelling after a tuberculin injection to determine if the reaction to the test is positive or negative. These are all forms of "testing" designed to assess the "performance" of our bodies and identify any issues that need attention. Negative viral test results mean the test did not detect the virus, but this doesn't rule out that the person could have an infection, showing how these results represent a snapshot around the specimen collection time. A single NAAT test can confirm an antigen test result, providing another layer of verification. This is, in a way, very similar to how a product is put through its paces on a track.

Even something like a skin biopsy or saliva samples being tested to detect rabies in suspect cases, or PCR on saliva being the standard laboratory test for diagnosing congenital CMV infection, with urine collected for confirmation, speaks to the depth of testing required for critical assessments. The Monospot test, though not always recommended for general use due to potential for antibodies caused by conditions other than infectious mononucleosis, still highlights the ongoing effort to refine diagnostic tools. The updated CDC recommendation for serologic diagnosis of Lyme disease, emphasizing that most tests detect antibodies that take weeks to develop, underscores the complexity and importance of accurate, timely testing. This continuous effort to refine and verify, whether for our health or for the products we use, is, honestly, a shared commitment to quality and safety.

What Happens at a Test Track Opening?

A test track opening is usually a moment of great excitement and anticipation. It’s not just a ribbon-cutting ceremony; it’s an event that often showcases the capabilities of the new facility and the innovations it will help bring to life. It’s a chance for the public, industry leaders, and media to get a first-hand look at where future breakthroughs will be proven. This kind of event, you know, really brings the whole concept to life.

A Glimpse into the Future

At a test track opening, visitors often get to see demonstrations of vehicles or products being put through their paces on the new surfaces. This might include high-speed runs, intricate handling maneuvers, or even simulated emergency braking tests. These demonstrations are designed to highlight the track's features and the advanced testing capabilities it offers. It’s a bit like getting a sneak peek at tomorrow's technology, seeing it in action before it becomes commonplace. This really shows what’s possible, and that’s pretty cool.

Such events also provide a platform for companies to announce new research initiatives or partnerships that will leverage the new track. It’s a moment to cast a vision for the future, emphasizing how this new facility will contribute to safer, more efficient, and more enjoyable products for consumers. It's a statement about progress and a commitment to innovation, and that's something we can all appreciate. These moments are, in fact, quite inspiring, showing us where things are headed.

The People Behind the Precision

While the track itself is impressive, the opening also shines a light on the dedicated people who will operate it: the engineers, technicians, and test drivers. These are the individuals with the expertise and experience to conduct the precise measurements and evaluations needed to ensure product quality. They are the ones who understand the nuances of performance and safety, translating complex data into actionable insights. Their skill and dedication are, honestly, just as important as the physical track itself.

The event often includes opportunities to meet these experts, to learn about their work, and to understand the meticulous processes involved in testing. This human element is crucial, as it reminds us that behind every successful product is a team of people committed to excellence. It’s a celebration of human ingenuity and the relentless pursuit of perfection, which, as a matter of fact, is something that truly drives progress in every field. Their work, like the detailed analysis of medical test results, is vital for ensuring everything is just right.

Why This Matters to Everyone

The opening of a new test track might seem like a niche event, perhaps only relevant to those in specific industries. But the truth is, the implications of such a facility stretch far beyond its immediate surroundings, impacting every one of us in significant ways. It's about the bigger picture of how products become reliable and safe, and that's something that touches all our lives. It really does matter, quite a bit, to be honest.

Building Trust in Products

At its core, a test track is about building trust. When products are rigorously tested in a controlled environment, it gives consumers confidence that what they are buying is safe, durable, and performs as advertised. This trust is essential for consumer satisfaction and for the reputation of manufacturers. It's the assurance that the car you drive will handle unexpected situations, or that the appliance you use daily will last for years. This is, you know, a very important part of our relationship with the things we buy.

Without such facilities, product development would be far riskier, leading to more recalls, safety concerns, and ultimately, a loss of public confidence. The investment in a test track is an investment in reliability, which benefits both businesses and the people who use their products. It’s a commitment to quality that translates directly into a better experience for everyone, which, at the end of the day, is what we all want from the things we use. So, in a way, it makes everything better.

Driving Future Advancements

Beyond current product verification, a test track serves as a crucible for future advancements. It’s where experimental designs are evaluated, new materials are put to the test, and innovative technologies are refined. This continuous cycle of testing and improvement drives progress across entire industries, leading to more efficient vehicles, safer transportation systems, and smarter solutions for everyday challenges. This is, actually, where many of the next big ideas get their start, so it's a really important place.

The data gathered on a test track provides invaluable insights that inform the next generation of products, pushing the boundaries of what's possible. It fosters a culture of innovation, encouraging engineers and designers to think bigger and bolder, knowing they have a dedicated space to validate their ideas. So, a test track opening is not just about today's products; it's about paving the way for tomorrow's breakthroughs, making our lives better and safer in ways we might not even imagine yet. It's a very exciting prospect, indeed, for all of us.

Frequently Asked Questions

What is the main purpose of a new test track opening?

The primary purpose of a new test track opening is to introduce a dedicated facility for rigorously evaluating products, particularly vehicles, under controlled conditions. It shows a commitment to ensuring quality, safety, and performance before items reach the public. It's a place where designs are put to the ultimate challenge, and that's very important.

How does a test track ensure product safety and reliability?

A test track ensures safety and reliability by providing diverse surfaces and scenarios to push products to their limits. This includes high-speed sections, handling courses, and challenging road simulations. Data gathered from these tests helps engineers identify weaknesses and make improvements, much like detailed health tests help doctors understand our bodies' performance. This leads to safer, more dependable items for everyone, you know.

Can the public visit a test track opening?

While some test track openings are private industry events, many do include public or media days, offering a chance to see demonstrations and learn about the facility's capabilities. It varies by location and the company involved. These events are often a great way to see cutting-edge technology in action and learn more about the meticulous work that goes into product development. You might find details on the company's official site or through industry news outlets. Learn more about product validation on our site, and link to this page for more on testing standards.

A Short History of Standardized Tests | JSTOR Daily

Test Preparation – International Language Institute (ILI)

Corona: Das gilt bei Corona-Tests | Bundesregierung